The successful execution of oil and gas operations not only brings prosperity to the UAE but also ensures the health, safety, and quality that the oil and gas industry needs to succeed. Temperature is the measurement that goes to the core of the process from the starting (extraction) to the end (refining). Resistance temperature detectors (RTDs) have become a crucial temperature-sensing technology, providing enhanced accuracy and long-lasting stability across a wide temperature range in a rigid environment.

This post will explain how RTDs are impacting the UAE’s oil and gas activity, the reasons for their selection over thermocouples, and their effective uses in this sector.

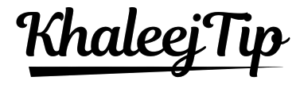

What is an RTD?

A resistance temperature detector is a temperature sensor that measures temperature by utilizing the change in resistance. They normally use pure platinum wire, which is identified by its outstanding linear and stable temperature resistance. The Platinum 100 is the most commonly used resistance temperature detector in the industry, characterized by a resistance of 100 ohms. Where thermocouples generate a voltage, these detectors are a resistance tool that provides a very high degree of accuracy over a wide temperature range.

Why Are Resistance Temperature Detectors Important In The Oil and Gas Sector?

Oil and gas operations are complicated processes that need consistency, accuracy, and safety. This is particularly evident in the UAE, where state-of-the art petrochemical plants and high throughput processes are common. Below are several good reasons explaining why resistance temperature detectors are indispensable within the oil and gas sector:

1. Increased Accuracy And Stability

Resistance temperature detectors offer a high degree of precision in reading, with amazing stability and repeatability over extended periods. When each degree is significant in refineries or LNG plants, even minor changes can result in a huge energy loss and potentially, safety issues. They can help in reducing these risks by providing reliable data.

2. Outstanding Performance in Harsh Environments

Even in seaward fixtures in the Persian Gulf or high-pressure pipelines in the desert, oil and gas companies all over the UAE are subjected to extreme temperatures, corrosive chemicals, and high mechanical stress. RTDs, which are provided within safety covers or explosion-resistant housings, are made for such contingencies and can normally be expected to provide constant, predictable operation.

3. Process Optimization

Effective temperature control can be used to decrease modification costs, such as avoiding the requirement to rearrange piping, excavate, or change the head. RTDs can be applied to lower energy consumption and enhance productivity, which are critical for profits and the environment. Temperature monitoring and recording at several refineries in the UAE lead to increased yield and lower emissions.

4. Incorporation Into Digital Systems

The present RTD generation is often integrated with SCADA and DCS systems, which are usually found in oil plants in the UAE. This connectivity allows real-time analytics, prognostic maintenance, and integration with the latest industry technologies, all of which contribute to better operational efficiency.

What Are The Uses Of RTDs In The Oil and Gas Industry of The UAE

The top applications of resistance temperature detectors are:

1. Storage Tanks

The best utilization of RTDs is to monitor the temperature of stored raw or refined oil products to minimize fire risk.

2. Pipeline Monitoring

These sensors maintain the optimum temperature to prevent wax or hydrate and to prevent forming.

3. Distillation Columns

Precise heating control of distillation processes in refineries for enhanced separation efficiency.

4. Heat Exchanger

The use of a resistance temperature detector in heat exchangers ensures a safe and efficient exchange of energy.

5. Gas Compression Packages

In gas compression packages, monitoring temperature control using RTDs helps in stopping overheating and equipment damage.

RTDs Vs. Thermocouples: Which Is The Best?

RTDs are highly durable over time and thus are effortless to calibrate. In the UAE, where health and safety standards are very high, RTDs are the best solution due to the degree of precision they offer.

Thermocouples are capable of measuring a wider variety of temperatures, but they generally have reduced accuracy and are less secure over time. The UAE’s growth towards automation and digitization in the oil and gas industry is preferred due to the stable signals from the RTDs.

Final Words

In the competitive and highly technical environment of the UAE’s oil and gas industry, resistance temperature detectors have now become a sign of operational quality. Their precision, toughness, and flexibility make them essential in conditions where even a minor error can cost a lot. As the UAE continues its journey toward a smarter and greener energy future, RTDs will come alongside, assuring the temperature control of things remains secure, effective, and in line with the future. If you want more details on these temperature detectors, you can scroll through the Tempsens.